In our laboratory in Domat/Ems Switzerland, ALGORDANZA researchers developed a process to create cremation diamonds using high pressure, high temperature (HPHT) technology. Our custom powerful and technologically advanced diamond-processing machines are able to replicate nature creating pressures of 870,000 pounds per square inch (PSI) and temperatures of 2,100° to 2,600° Fahrenheit.

This procedure is called high-pressure-high-temperature-one-crystal-synthesis. And it is this very procedure adapted from nature’s diamond creation process that is used to create ALGORDANZA Memorial Diamonds. Our diamond synthesis process is outlined in the eight stages below:

The Process: How is a Memorial Diamond created?

Stage 1 – Carbon Isolation

Carbon is the basis of all life and is the foundation for diamond synthesis.

During cremation, most carbon escapes as carbon dioxide and the cremation ashes contain only one to five percent carbon.

In the process of transforming ashes to diamonds, our laboratory isolates this carbon from the vast range of chemical elements present in the cremation ashes. Following the example set by nature, this isolated carbon is used as the foundation for the diamond growth.

One pound of cremated remains or ten grams of hair is required to synthesize one or more cremation diamonds. The average adult human produces between five and ten pounds of cremation ashes.

Upon receipt of the cremated remains, our laboratory assigns a unique reference number to the provided cremated remains or sample, and this reference code is used to audit the entire transformation of your unique memorial diamond.

Stage 2 – Conversion to Graphite

Using our own specialized procedure, the cremation ashes are filtered using an acidic process and high temperature. The ashes are filtered again and again until a 99.9% carbon sample is reached.

The next step in the memorial diamond creation process is for heat and pressure to be applied and a graphite structure to form. This intermediate step in the process of transformation from carbon to a diamond is known as graphitization.

Stage 3 – Diamond Cell Growth

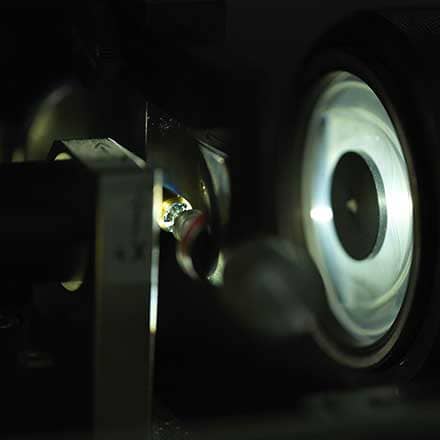

The next stage in transforming ashes to diamonds is to place the graphite in a growing cell in a High Pressure High Temperature (HPHT) press and expose it to 870,000 pounds per square inch (PSI) of pressure and temperatures of 2100° to 2600° Fahrenheit.

Inside of ALGORDANZA’s custom HPHT machines, the graphite structure slowly transforms into a diamond.

Stage 4 – Rough Diamond Removal and Cleaning

The longer the diamond remains in the growing cell the larger the diamond becomes. When the diamond has been in the growing cell long enough to create the desired size diamond, the growing cell is removed from the high pressure machines.

At the core of the cell, embedded in molten metal, lies the rough diamond which is then carefully cleaned in an acid bath.

Stage 5 – Cut and Polish

Our experienced experts can then hand cut your memorial diamond to create a one-of-a-kind brilliant, emerald, asscher, princess, radiant or heart shaped stone or if a rough diamond is desired, the rough diamond will be polished so that it shines in its unique form.

Stage 6 – Laser inscription

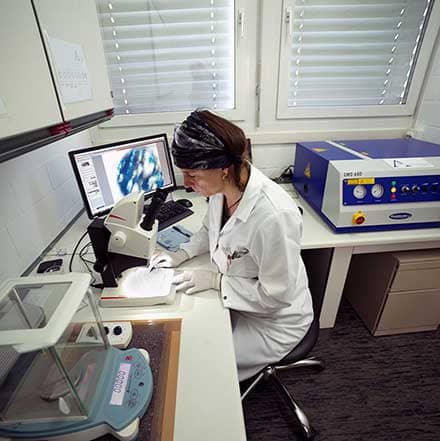

Every ALGORDANZA Memorial Diamond is engraved with a small laser inscription on the diamond’s girdle that includes the ALGORDANZA signet and the unique reference number of the order.

Upon request, a personal message can also be engraved. The laser inscriptions will only be visible under a microscope with 30 times magnification.

Stage 7 – Certification and Guarantee

Each ALGORDANZA Memorial Diamond is extensively documented and is accompanied by a certificate guaranteeing the carbon origin, authenticity, cut and clarity and other specific characteristics of the cremation diamond. Each certificate is signed by Rinaldo Willy, founder of ALGORDANZA.

Stage 8 – The Finished Memorial Diamond

The finished memorial diamond is laid in its very own diamond casket and family members may choose to personally pick up their memorial diamond in Switzerland or have it shipped by courier.

We encourage you to visit our US facilities or our laboratory in Switzerland and see for yourself how we transform ashes to diamonds.